Data from the motor, feedback, I/O devices, and other components can all be sent from servo drives along a network bus to the controller, where it can all be compiled and made available over the web. using megaTin圜ore, to create and output PWM any GPIO pin. This makes them perfect for Industry 4.0 (Industrial Internet of Things) machines and robots. Industry 4.0īy design, our servo drives connect to many components within a motion control system and collect data from them. CANopen, RS232 and RS485 have lower data rates but still meet the requirements for applications such as automotive, simple lab automation, and electric mobility. Analog Voltage to PWM Signal Converter, 0-5V/0-10V Analog Input Voltage to 0-100 PWM Signal 2KHZ-20KHZ Converter Module,for PWM Motor Speed Control Interface Circuit Activity 5. Their higher data rates and better real-time performance are ideal for applications such as collaborative robots, CNC machining, plasma cutting, semiconductor processing, and others. Network OptionsĪvailable network connections for centralized or distributed servo systems include EtherCAT, Ethernet TCP/IP, Ethernet/IP, Ethernet POWERLINK and more. Best of all, Click&Move® can operate from a PC, a Motion Automation Control Card, or even on AMC Servo Drives. Click&Move® easily manages the network communication protocols, HMI, logic control, coordinated motion, and just about anything you can throw at it. In addition, our Click&Move® automation system solves many of the dilemmas machine builders often face. Motion Engine allows our servo drives to store and execute indexed and sequenced moves giving them stand-alone capability without the need for a controller. Our FlexPro ® and DigiFlex ® Performance™ servo drives have Motion Engine built into them. In the event that our standard products don't meet a customer’s need, then we’re ready and able to create modified or custom servo drive solutions that do. Please note that adaptor cables are now available on Ali Express if you want to buy a premade cable. The advantage of linear amplification is its ability to faithfully reproduce oscillator waveforms with very high small signal bandwidth and low output distortion.

#Amx to pwm converter series

Please consult Table 1-5 in the technical reference guide for the functionality of each rail. Our Linear AC Power Sources (New LMX Series and Legacy AMX Series ) produce low-distortion, high fidelity, output waveforms. Continuous improvement provides and unending variety of new possibilities in drive intelligence, size, and power density for embedded motion control solutions. Please help im trying to convert my psu cooler master RM850 to rescue 003 Hp z800 mothernoard. Our FlexPro® and DigiFlex® Performance™ digital drives are capable of precise torque, velocity, and position control for AC and DC brushless servo motors, DC brush type servo motors, linear and rotary servo motors, closed loop vector motors, voice coils, inductive loads and actuators. Our AxCent™ drive family is a collection of easily-configurable analog servo drives perfect for centralized servo motor control schemes. Was this a useful electronics tip? If so, please cast your vote for it in the.AC servo drives and DC servo motor controllers are available for general servo automation or specific robot control. For more details on this subject as well as calculating R & C values more suitable for your application, please consult. For the Arduino, an R value = 3.9K and a C value = 0.1uF works well for most applications. The simple RC low-pass filter shown in the third photo converts the PWM signal to a voltage proportional to the duty cycle. All that is needed is a simple low-pass filter made from a resistor and a ceramic capacitor. Creating a real DAC Fortunately, it is easy to convert a PWM output to an analog voltage level, producing a true DAC.Īmazon S3 File Upload Api Company.

#Amx to pwm converter pdf

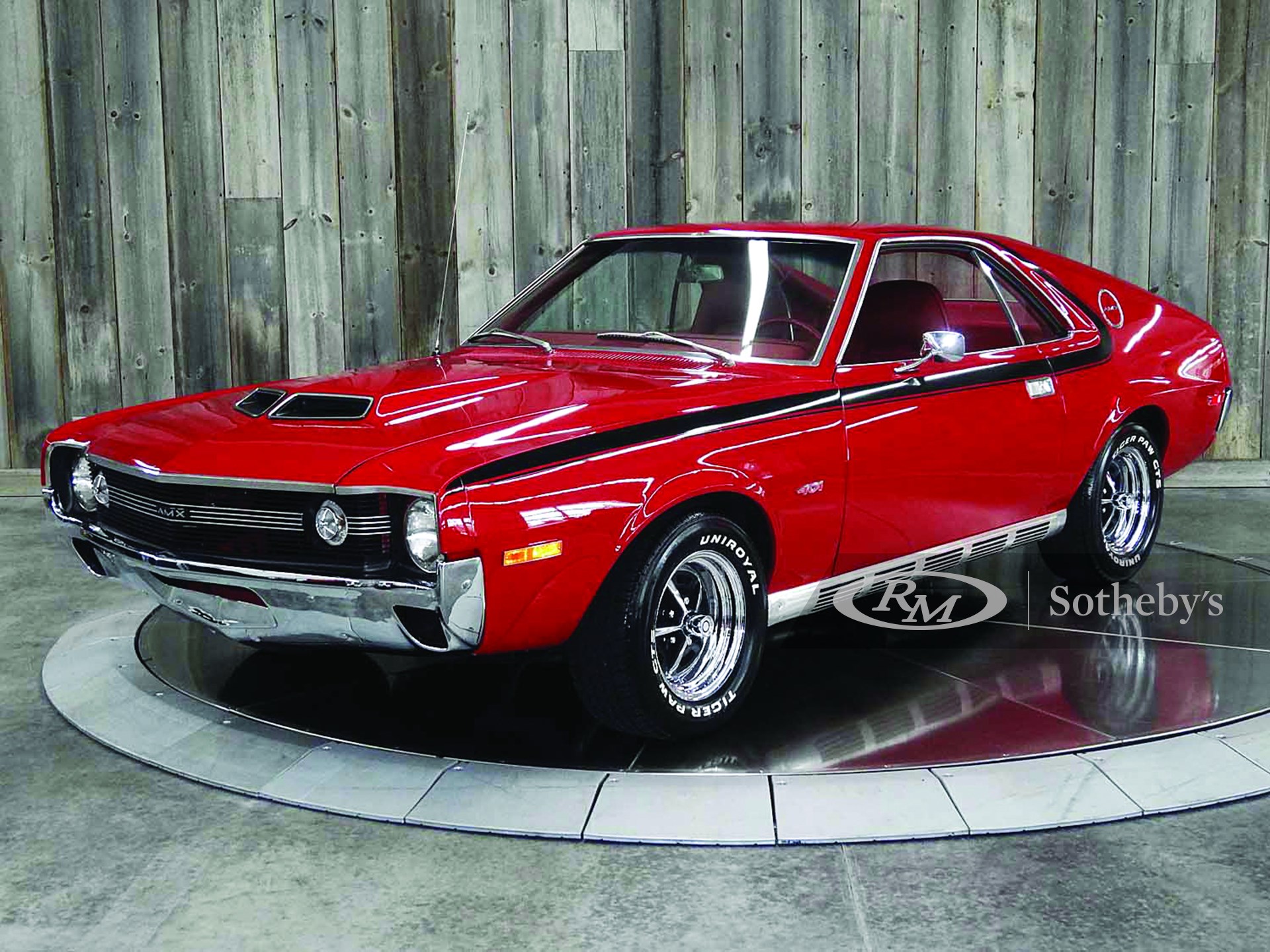

Libro Civilizaciones De Occidente Vicente Reynal Pdf Converter more. The AMX Series is a family of High Performance Linear AC power sources covering the power range from 500 VA to 12 kVA.

For many applications, such as the case of motor control, PWM is sufficient.įor other applications, such as creating a linear voltage or current driver, a real DAC is needed. The name seems to imply DAC functionality, but it just controls the PWM output. The Arduino library provides this functionality with a function called analogWrite(). Instead they provide pulse-width modulated (PWM) outputs (see second photo). You might think that they also provide the converse which is digital to analog (DAC) conversion. Subject: RE: PPM (RC) to PWM converter.Īrduino's and other microcontrollers provide analog to digital (ADC) conversion to convert an input voltage to a digital value. The switching back and forth is the easy part, I have some switching circuits that take a PPM signal and switch. Mobile Audio & Video Products such as Amplifiers, Subwoofers, Speakers, Multimedia Source Units, Universal Headrests, Overhead Monitors. Amx To Pwm Converter Circuit 3,6/5 1321reviewsĪmx To Pwm Converter.

0 kommentar(er)

0 kommentar(er)